close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

The Automatic Coiling and Wrapping Machine is a highly advanced and efficient piece of industrial equipment designed to streamline the processes of coiling and wrapping various materials. It is widely applicable in industries such as wire and cable manufacturing, metal processing, textiles, and packaging, where the need to neatly coil and securely wrap products is essential.

This machine is typically composed of several key components. The coiling mechanism is responsible for neatly winding the material into a coil of a specific diameter and shape. It can handle a wide range of materials, from thin wires and cables to thicker strips and rolls. The wrapping system then takes over, applying a protective layer, such as plastic film, paper, or fabric, around the coiled material to safeguard it from dust, moisture, and physical damage. Additionally, an automatic control system oversees the entire operation, ensuring precise coordination between the coiling and wrapping

processes and allowing for easy adjustment of parameters.

One of the most outstanding features of the Automatic Coiling and Wrapping Machine is its high level of automation. Once the initial settings are configured, the machine can operate continuously with minimal human intervention. The automatic control system monitors and adjusts factors such as coiling speed, wrapping tension, and the amount of wrapping material used. This not only increases production efficiency but also reduces the potential for human error, resulting in consistent and high-quality output.

This machine is engineered to work with a diverse array of materials. For the wire and cable industry, it can handle copper wires, aluminum wires, fiber optic cables, and more. In the metal processing field, it can coil metal strips, sheets, and rods. In the textile industry, it is capable of coiling yarns and threads. The ability to adapt to different materials makes it a valuable asset for various manufacturing and packaging operations.

The Automatic Coiling and Wrapping Machine offers great flexibility in terms of coiling and wrapping specifications. The coiling diameter, number of layers, and pitch can all be adjusted according to specific product requirements. Similarly, the type of wrapping material, the wrapping pattern (such as spiral or overlapping), and the tension applied can be customized. This allows manufacturers to meet the unique needs of their products and customers, whether it's for aesthetic purposes or enhanced protection.

Safety features are an integral part of this machine. It is equipped with sensors and emergency stop buttons to prevent accidents during operation. The robust construction and high-quality components ensure the machine's reliability, reducing the likelihood of breakdowns and minimizing downtime. This is crucial for maintaining a smooth production flow and meeting production schedules.

The automated operation of the machine significantly speeds up the coiling and wrapping process. It can complete tasks much faster than manual methods, allowing businesses to increase their production output. For example, in a wire manufacturing plant, the machine can coil and wrap large quantities of wires in a short time, enabling the company to meet market demands more promptly.

The wrapping process carried out by the machine provides excellent protection for the coiled products. By applying a protective layer, it shields the materials from external factors that could cause damage, such as corrosion, abrasion, and contamination. This helps to maintain the quality of the products during storage and transportation, reducing the risk of losses due to product degradation.

While the initial investment in an Automatic Coiling and Wrapping Machine may be significant, it can lead to long-term cost savings. By reducing the need for manual labor, businesses can cut down on labor costs. Additionally, the machine's ability to optimize the use of wrapping materials reduces material waste, further contributing to cost savings. The reliability of the machine also means fewer maintenance and repair costs over time.

The neatly coiled and uniformly wrapped products produced by the machine have a more professional and appealing appearance. This can enhance the brand image of a company and make its products more attractive to customers. In industries where product presentation is important, such as consumer goods and luxury items, the aesthetic benefits of the machine can be a significant competitive advantage.

Our team of experienced technicians will provide on-site installation services to ensure that the Automatic Coiling and Wrapping Machine is properly set up and integrated into your production line. We also offer comprehensive training programs for your operators, covering all aspects of machine operation, maintenance, and troubleshooting. Our goal is to ensure that your team can operate the machine effectively and efficiently from the start.

We maintain a large inventory of high-quality spare parts for the machine to ensure quick and timely replacement in case of any component failures. Our spare parts are sourced from reliable suppliers and are guaranteed to be compatible with the original machine. We offer a fast delivery service to minimize downtime and keep your production running smoothly.

Our technical support team is available 24/7 to assist you with any technical issues or questions you may have. Whether it's a problem with the coiling mechanism, the wrapping system, or the control system, we will respond promptly and provide effective solutions. We also offer remote monitoring and diagnostic services to quickly identify and resolve problems, reducing the need for on-site visits in some cases.

We offer a generous warranty period for the Automatic Coiling and Wrapping Machine. During this period, we will repair or replace any defective parts free of charge. Additionally, we provide regular maintenance services to keep the machine in optimal condition. Our maintenance services include routine inspections, lubrication, calibration, and adjustment of components, ensuring the long-term reliability and performance of the machine.

Model | Height(mm) | OD(mm) | ID(mm) | Wire Dia(mm) | Wrapping Materials | Average Coil output speed (100m/Coil) |

CP1040 | 50-120 | 180-400 | 120-200 | 3-10 | PVC | 2-3coil/min |

CP1246 | 50-120 | 180-460 | 120-200 | 2.5-8 | PVC | 2-2.5coil/min |

CP1860 | 70-180 | 280-600 | 160-300 | 4-15 | PVC | 1-1.5coil/min |

CP2480 | 120-240 | 360-800 | 250-400 | 10-25 | PVC woven belt | 0.5-1coil/min |

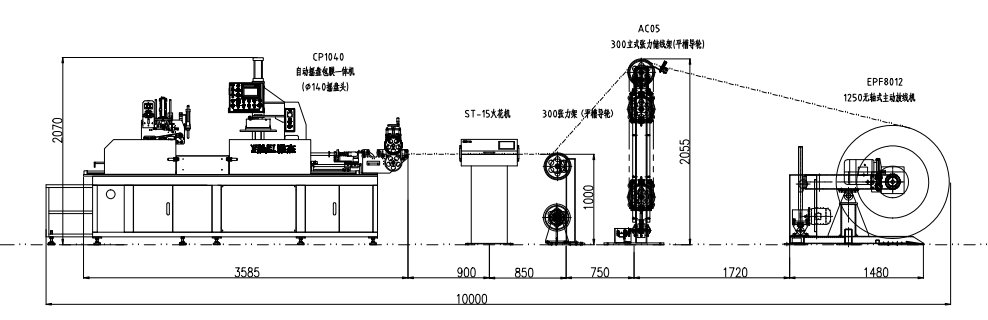

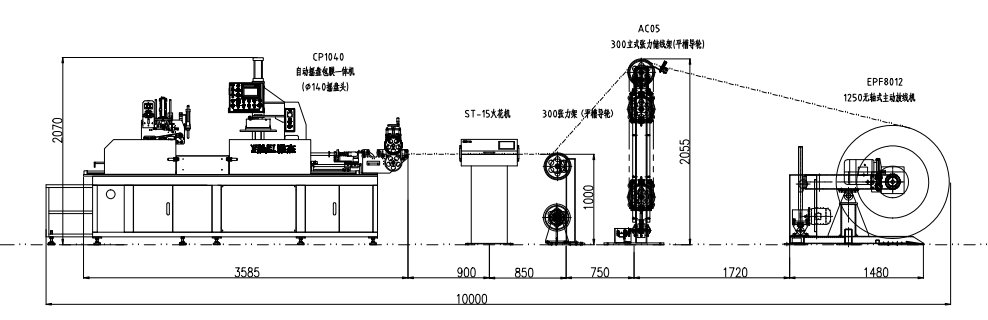

The Lay-out of machine as following:

The Automatic Coiling and Wrapping Machine is a highly advanced and efficient piece of industrial equipment designed to streamline the processes of coiling and wrapping various materials. It is widely applicable in industries such as wire and cable manufacturing, metal processing, textiles, and packaging, where the need to neatly coil and securely wrap products is essential.

This machine is typically composed of several key components. The coiling mechanism is responsible for neatly winding the material into a coil of a specific diameter and shape. It can handle a wide range of materials, from thin wires and cables to thicker strips and rolls. The wrapping system then takes over, applying a protective layer, such as plastic film, paper, or fabric, around the coiled material to safeguard it from dust, moisture, and physical damage. Additionally, an automatic control system oversees the entire operation, ensuring precise coordination between the coiling and wrapping

processes and allowing for easy adjustment of parameters.

One of the most outstanding features of the Automatic Coiling and Wrapping Machine is its high level of automation. Once the initial settings are configured, the machine can operate continuously with minimal human intervention. The automatic control system monitors and adjusts factors such as coiling speed, wrapping tension, and the amount of wrapping material used. This not only increases production efficiency but also reduces the potential for human error, resulting in consistent and high-quality output.

This machine is engineered to work with a diverse array of materials. For the wire and cable industry, it can handle copper wires, aluminum wires, fiber optic cables, and more. In the metal processing field, it can coil metal strips, sheets, and rods. In the textile industry, it is capable of coiling yarns and threads. The ability to adapt to different materials makes it a valuable asset for various manufacturing and packaging operations.

The Automatic Coiling and Wrapping Machine offers great flexibility in terms of coiling and wrapping specifications. The coiling diameter, number of layers, and pitch can all be adjusted according to specific product requirements. Similarly, the type of wrapping material, the wrapping pattern (such as spiral or overlapping), and the tension applied can be customized. This allows manufacturers to meet the unique needs of their products and customers, whether it's for aesthetic purposes or enhanced protection.

Safety features are an integral part of this machine. It is equipped with sensors and emergency stop buttons to prevent accidents during operation. The robust construction and high-quality components ensure the machine's reliability, reducing the likelihood of breakdowns and minimizing downtime. This is crucial for maintaining a smooth production flow and meeting production schedules.

The automated operation of the machine significantly speeds up the coiling and wrapping process. It can complete tasks much faster than manual methods, allowing businesses to increase their production output. For example, in a wire manufacturing plant, the machine can coil and wrap large quantities of wires in a short time, enabling the company to meet market demands more promptly.

The wrapping process carried out by the machine provides excellent protection for the coiled products. By applying a protective layer, it shields the materials from external factors that could cause damage, such as corrosion, abrasion, and contamination. This helps to maintain the quality of the products during storage and transportation, reducing the risk of losses due to product degradation.

While the initial investment in an Automatic Coiling and Wrapping Machine may be significant, it can lead to long-term cost savings. By reducing the need for manual labor, businesses can cut down on labor costs. Additionally, the machine's ability to optimize the use of wrapping materials reduces material waste, further contributing to cost savings. The reliability of the machine also means fewer maintenance and repair costs over time.

The neatly coiled and uniformly wrapped products produced by the machine have a more professional and appealing appearance. This can enhance the brand image of a company and make its products more attractive to customers. In industries where product presentation is important, such as consumer goods and luxury items, the aesthetic benefits of the machine can be a significant competitive advantage.

Our team of experienced technicians will provide on-site installation services to ensure that the Automatic Coiling and Wrapping Machine is properly set up and integrated into your production line. We also offer comprehensive training programs for your operators, covering all aspects of machine operation, maintenance, and troubleshooting. Our goal is to ensure that your team can operate the machine effectively and efficiently from the start.

We maintain a large inventory of high-quality spare parts for the machine to ensure quick and timely replacement in case of any component failures. Our spare parts are sourced from reliable suppliers and are guaranteed to be compatible with the original machine. We offer a fast delivery service to minimize downtime and keep your production running smoothly.

Our technical support team is available 24/7 to assist you with any technical issues or questions you may have. Whether it's a problem with the coiling mechanism, the wrapping system, or the control system, we will respond promptly and provide effective solutions. We also offer remote monitoring and diagnostic services to quickly identify and resolve problems, reducing the need for on-site visits in some cases.

We offer a generous warranty period for the Automatic Coiling and Wrapping Machine. During this period, we will repair or replace any defective parts free of charge. Additionally, we provide regular maintenance services to keep the machine in optimal condition. Our maintenance services include routine inspections, lubrication, calibration, and adjustment of components, ensuring the long-term reliability and performance of the machine.

Model | Height(mm) | OD(mm) | ID(mm) | Wire Dia(mm) | Wrapping Materials | Average Coil output speed (100m/Coil) |

CP1040 | 50-120 | 180-400 | 120-200 | 3-10 | PVC | 2-3coil/min |

CP1246 | 50-120 | 180-460 | 120-200 | 2.5-8 | PVC | 2-2.5coil/min |

CP1860 | 70-180 | 280-600 | 160-300 | 4-15 | PVC | 1-1.5coil/min |

CP2480 | 120-240 | 360-800 | 250-400 | 10-25 | PVC woven belt | 0.5-1coil/min |

The Lay-out of machine as following: